Control of Hot Work

(DESCRIPTION)

A man stands up beside a table and faces us. His chair has a yellow safety vest draped over the back, and a white safety helmet sits on the table. He sets a welding torch down.

(SPEECH)

You wouldn't believe how many fires are caused by hot work. That's welding, cutting equipment, blowtorches, and grinding wheels-- anything that generates heat, sparks or fire. Any type of hot work is a potential risk.

[MUSIC PLAYING]

(DESCRIPTION)

Logo: Travelers. Text: Control of Hot Work. An animated worker welds an overhead pipe. Sparks fall.

(SPEECH)

Sparks and globules of molten metal go flying and can land on flammable material.

(DESCRIPTION)

The sparks fall into a nearby box and onto the floor.

(SPEECH)

The fire may not even start immediately, but may smoulder undetected for some time before igniting.

(DESCRIPTION)

A clock appears. The hands turn around it. Then the sparks on the floor turn into flames. Nearby, two men exchange a clipboard. Now, the boxes and floor near the welding site are covered in thick blankets, and a fire extinguisher sits nearby.

(SPEECH)

Reduce the risk with a permit to work system, strong management support, and employees that are properly trained.

If you're bringing in contractors, make sure that they are reputable. Follow the requirements of your hot work permit, and make sure that they are supervised. To find out more, visit the website below or speak to your broker.

[AUDIO LOGO]

(DESCRIPTION)

Text: Get more safety tips at www.travelers.co.uk/riskcontrol. A video preview plays above. Text: Next tip. Share the Safety. Logo: Linked In. Text: The information in this video is intended for use as a guideline and is not intended as, nor does it constitute, legal, technical or professional advice. Travelers does not warrant that adherence to any recommendations, best practices, or guidelines will result in a particular outcome. In no event will Travelers or any of its subsidiaries or affiliates be liable to anyone who has access to or uses the information provided in the video. Copyright 2016 Travelers Management Limited. Travelers and the Travelers Umbrella logo are registered trademarks of The Travelers Indemnity Company in the U.S. and other countries.

Risk management advice for cutting, welding or other hot work

Cutting, welding and other hot work operations present a major fire risk to organisations. Most often, these fires start because of carelessness or ineffective supervision while hot work is occurring. Fires from cutting, welding and other hot work operations have generated multi-million pound losses in the United Kingdom. Fortunately, these losses are largely preventable when those responsible take specific precautions.

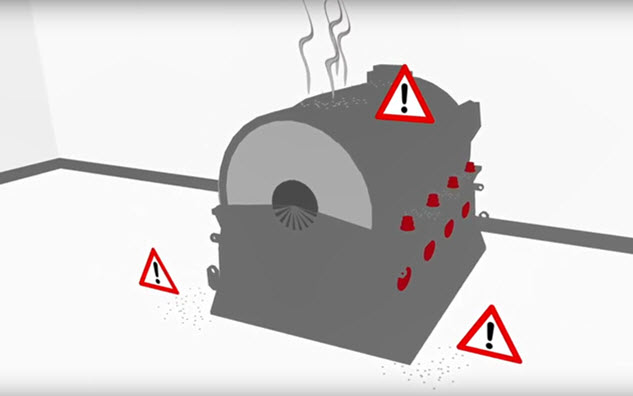

Hot work includes any operation that generates heat, sparks or flame – often from sources like gas and electric cutting and welding equipment, blow lamps and blowtorches, grinding wheels and cutting discs, and bitumen and tar boilers. When a fire occurs as a result of hot work, it’s often because molten globules of metal roll distances or fall through cracks onto unseen combustibles.

What are the most common reasons for hot work fires?

- Inadequate preparation of the work site.

- Outside contractors failing to comply with hot work precautions.

- Poor housekeeping.Failure to maintain fire watches or to provide adequate fire extinguishing equipment.

- Defective equipment.

What precautions should an organisation take when undertaking hot work?

- Issue a hot work permit as part of a formalised permit system

- If a contractor is used, only select contractors who have properly trained personnel and understand the risks involved.

- Advise contractors about any flammable materials or hazardous conditions that require special care.

- Ensure the contractor has adequate insurance and understands if their policy has restrictions related to hot work.

- Create a written contract that specifies the standards of conduct for contractors and clearly establishes responsibility for liability in the event of a loss.

When should a hot work permit be used?

- A hot work permit must be in place when hot work cannot be conducted in designated, properly safeguarded areas such as maintenance workshops or detached outside locations, or it is conducted by outside contractors or other non-employees.

- The permit should only be issued after a trained supervisor has assessed the area and verified that all safety precautions are being taken.

For more information, sign up to our Risk Academy, log in to the Risk Control Customer Portal, or email contactriskcontrol@travelers.com